Unstable prices of fossil fuels drives the public and private sectors in search of alternative, reliable and affordable energy sources. Environmental awareness, successfully lobbied in government, politics and finance, plays no less of a role. Two of the prominent energy sources referred to as renewable are solar and wind energy. Various types of wind turbines harvest wind energy. The primary conversion of solar energy is performed via photovoltaic (PV) panels. However, solar thermal technology is in use as well.1

- >

- Home

- >

- Renewable Energy

PROFIT-EFFECTIVE MANAGEMENT OF RENEWABLE ENERGY

The ROI Challenge

The design of such systems, which are ultimately geared towards revenue made off the energy generated and sold, often overlooks important aspects, which compromise ROI and system profitability.

Among the parameters which considerably affect profitability and revenue are:

- Erroneous utility readings resulting in compromized revenue

- Subpar system accuracy in monitoring energy

production, resulting in:

- Failure to utilize systems at maximum capacity

- Failure of equipment due to inferior power quality, introduced by the grid (e.g. harmonics)

An advanced energy management system, which includes accurate metering hardware and desktop software, is crucial for gaining insight into the above and generating the needed alerts.

The SATEC Renewable Offer

Worldwide Presence and Experience

SATEC offers solutions for renewable energy metering. The Siemens GAMESA Hybrid Park (Spain, solar & wind), Sinovel wind turbines (China), Perovo solar park (the Ukraine), EDF (France), IEC (Israel Electric Corporation) and Suzlon (India) are examples for SATEC projects. The SATEC system includes functionalities and advantages, corresponding with the challenges mentioned.

1. An Independent Metering System

Utilities often process erroneous calculations,2 overcharging for imported energy and underpaying for renewable energy exported to the grid.3 Placing a reliable and non-biased

revenue-grade SATEC meter at the connection to the grid guarantees supervision over the utility’s bi-directional TOU energy metering/billing. The EM720 is an ideal example of such an advanced

high-accuracy (Class 0.2S, per IEC 62053-22) revenue grade meter which combines power quality analysis as well (Class A, per IEC 61000-4-30).

2. An Accurate Metering System

Accuracy itself has a direct impact on revenue: a 1000 kVA transformer, operating at a typical 80% load, 0.9 PF, with electricity purchase at a

USD0.15/kWh rate is a typical scenario. With these parameters, the resulting difference between the allowed reading error for a Class 0.5 meter and a Class 0.5S (per IEC 62053-22) using SATEC HACS (High Accuracy Current Sensors) would translate to USD 9,461 annually (! for details, please refer to SATEC’s Accuracy Class application note).

Accordingly, all SATEC meters feature a minimum Class 0.5S accuracy (and Class 0.2S). Use of the HACS CTs, as a “One-CT” system, raises accuracy even beyond the mentioned standard, by eliminating the error factor of external CTs.

To illustrate this point further, basically, all PV panels rely on DC/AC inverters. These feature basic power metering functionality, often mistakenly seen as a reliable monitor. However, these readings are often far from accurate, starting at 2% accuracy with ideal loads, running through a typical 5% permissible error, reaching at times up to 50% permissible error. The above data is non- biased and is stated in official handbooks.

DC METERING

SATEC introduces additional accuracy and insight into the energy balance by offering DC metering capability (via Hall Sensors). Monitoring DC production current, prior to inversion, provides

a health-check on inverter efficiency and overall system architecture efficiency4 as well. This is available with SATEC’s PRO Series power meters, which feature advanced communication interfaces and functionality.

3. Optimization: An effective Production & Revenue Dashboard

SYSTEM EFFICIENCY

A comprehensive and accurate metering network ensures real-time monitoring of system

performance vs. its optimal architectural capacity, often hampered by malfunctioning equipment, dirty solar cells, shading or degradation of cells5 etc. This energy management system provides

a comparison of predicted vs. actual metered production, flagging any drop in production, locating the problematic component.

ENHANCED RESOLUTION

The more junctions of energy production designated as metering points, the higher the resolution. Increased system resolution enables obtaining a comprehensive energy balance / snapshot, detecting and pinpointing energy leaks or equipment failure along the internal network.

THE DESKTOP DASHBOARD

Expertpower is a software suite offered either as Software as a Service (SaaS) or as a standalone installation. Communicating with the physical

metering network, it is a dashboard displaying near-real-time data and analysis of production and revenue.

Expertpower is a versatile tool, providing different levels of analysis and allowing drill- down resolution into timeframes, up to 5-minute increments. Data is displayed in a variety of visual means: charts, graphs and heat-maps, facilitating anomaly detection. Irregularities are also flagged by alerts, which are sent out to designated users.

Designed as a modular platform, dashboards can be personalized and specified reports can be generated on demand. To enable retrofit and

integration with existing metering infrastructure, it is interoperable with equipment of any make.

REAL-TIME FINANCIAL DATA

The combined system (hardware and software) allows monitoring real-time data resulting in immediate and accumulative saving in energy, increased revenue and reduced carbon emissions

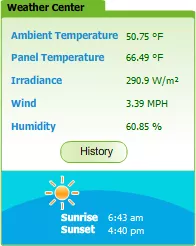

FORECASTING ENERGY PRODUCTION

Expertpower includes a module for prediction of energy production, based on system capacity and efficiency and weather forecasting. Production forecasting is extremely important for energy retail, especially for IPPs, which must report their forecasts to the dispatch and control center, setting their quota of supply vis-à-vis demand.

4. Power Quality

Placing a SATEC Power Quality Analyzer, (revenue grade, such as the EM720/PM180) at the grid connection ensures detection of power quality deviations from standard such as upstream harmonics, outages, sags, swells etc., which harm equipment and hamper production.

Positioning a power quality analyzer at the grid connection also allows a producer to claim compensation from the utility for loss of production due to such equipment failure, due to faulty power quality. Deploying a metering network enables real-time monitoring of voltage

and current measurements, providing extra insight into the system’s power quality.

Inverters themselves include components which are prone to failure. These include capacitors, for example, which can dry out or burn due to external spikes in voltage. The result of this is increased harmonics, injected to the network.

Grid regulations normally limit tolerance of such harmonics at 8% THD, as set in EN50160.6 Anything beyond this, requires disconnecting the PV plant and loss of production. Flagging such inverters ensures unhampered production.

EXCEPTIONAL FREQUENCY RESOLUTION

The nature of the complicated integration of wind, solar or battery-stored energy into the utility grid requires rigorous monitoring of the frequency

of both generated power and grid frequency to which the power is introduced. SATEC meters delivers unique reading resolutions at 0.001Hz, at extremely high accuracy, enabling enhanced synchronization and minimal system idling.

Conclusion

With profitability and ROI being decisive factors

in justifying investment in renewable energy, the factors described must be addressed. Designing and integrating a SATEC control system will promote your energy production facility to the level of a true profit center.

Notes

- http://www.brightsourceenergy.com/ashalim-solar-project#.YKT5nagzZaQ, a SATEC project

- https://www.cbc.ca/news/canada/calgary/enmax-bill-calgary-mistake-electricity1.5880933

- https://www.ewov.com.au/common-complaints/billing-mistakes

- https://www.electronicdesign.com/markets/energy/ article/21794160/dont-judge-a-solar-pv-systems-efficacy-by- inverter-efficiency-alone

- https://www.solarpowerworldonline.com/2017/06/causes-solar-panel-degradation/